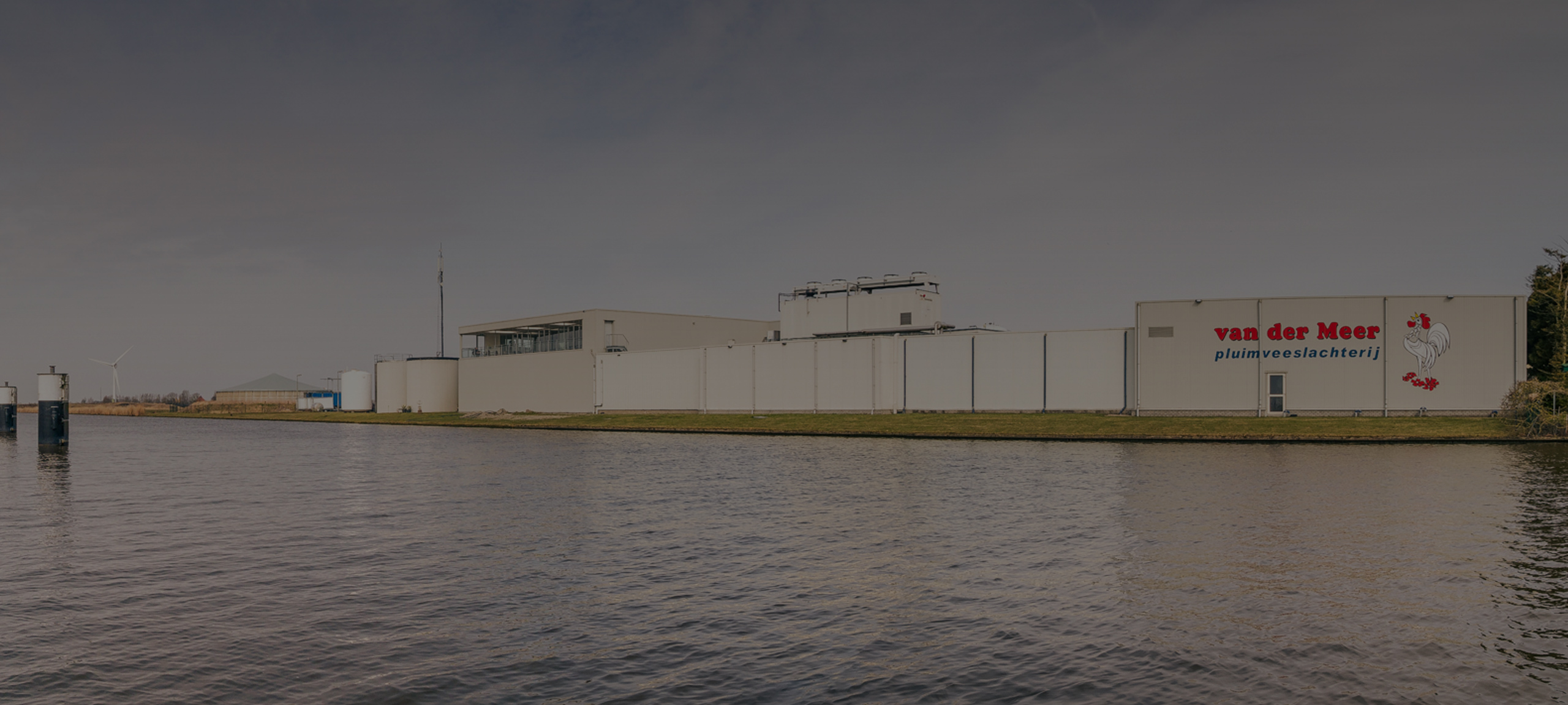

It Heech 44, 9035 AE Dronryp, The Netherlands | info@wvandermeer.nl | +31 517231641 | www.wvandermeer.nl

W. van der Meer en Zonen

A company with a history since 1935!

A company with a history since 1935!

In 1935, the building in which the poultry processor is currently housed, was purchased by Wytze van der Meer, the company’s founder. Initially, he specialised in the trade in wool producing cattle, poultry and rabbits, but soon chickens were eviscerated and the brand name WMD (Wytze van der Meer Dronrijp) came into being.

The family business has been able to expand into what it is today: a modern factory in which 48 persons with the right expertise ensure the high quality of our end product: the boiling-hen.

Vision

To deliver a safe stewing hen product at a reasonable price. W. van der Meer and Zonen B.V. treats her employees, the animals, the equipment and the environment in a sustainable way, as a good family man would do. As processors of the by-product of the eggindustry, the stewing hen, we are well aware of our responsibility towards the society, animals and the environment.

In the Van der Meer family we are proud of our company and of the way we may run our day-to-day operations with our tight-knit group of employees.

Production process

The live poultry is only sourced at approved poultry farms. These suppliers are evaluated every six months. Our own transport and drivers bring the live animals to the slaughterhouse with care, where the animals undergo the following steps in the production process:

• At delivery, the crates are unloaded and placed in the holding area. Next, the animals are unloaded, put on the slaughterline and stunned. Via the slaughterline the animals are transported to the different departments;

• At the plucking area, the chickens are bled and the feathers removed;

• In the evisceration room, all carcasses are individually checked and organs are removed;

• In the chilling room, the carcasses are chilled with cold water and placed on the weighing line after sorting for A- and B-quality;

• At the packing station, animals are weighed individually and sorted per weight class. Carcasses of B-quality are automatically cut-up into different chicken parts and/or further processed into mechanically separated 3mm meat.

• In the freezer, carcasses and chicken cuts are deep frozen, stored and finally transported to the customer.

Quality and Sustainability

In our company, quality and food safety have been central ever since we started. To ensure the quality of our products, resulting in satisfied customers and secured continuity, our quality system has been certified for the ISO22000 standard.

Since 2009, W. van der Meer en Zonen B.V. has had a quality management system based on the ISO22000 standard. ISO22000 is an ISO standard in which requirements are made on an organisation in the food chain. The ISO22000 standard is primarily a food safety management system into which an HACCP system and a GHP (Good Hygienic Practices) have been integrated.

ISO22000 emphasises food safety, adding food safety policy/management to quality policy/management. Quality can be defined as everything the customer expects; of course this includes food safety.

Distribution

Distribution

To guarantee the quality of our products, all processes are done in-house. Our own drivers pick up the live chicken in the Netherlands and Germany.

We aim to deliver the end-product directly to our customers in the Netherlands and Belgium with our own transport. Containers for the export outside of Europe are loaded under our own supervision, despite the fact that most containers are sold ex-works.

Products

• Whole hens 1000gr – 1500gr individually packed in polybags (IWP)

• Whole hens naked/bulk packed 10kg

• 10 kg hen legs

• 10 kg hen whole wings

• 10 kg feet

• 10 kg hen combs

• 10 kg hen backs

• hen necks, naked packed/block frozen

All these products can be delivered both from conventional farms, as well as free range or organic.